Keeping a shell intact

- Electronic egg.

- Measuring shocks to eggs.

- Useful from rearing to packing center

- Real-time tracking on a tablet application.

Keeping a shell intact

WHY TO CHOOSE CRACKLESSEGG™ :

CRACKLESSEGG: THE IDEAL AUDIT TOOL FOR THE ENTIRE PRODUCTION CHAIN

|

Before eggs can be hatched or consumed, the egg goes a long way. The latter can be chaotic: the egg is picked, sorted, washed, packed and transported several times. All these steps give it the opportunity to undergo many shocks with other eggs or pickup and sorting equipment. In the event of an impact the egg cracks. This considerably reduces its sanitary quality. A fall in the quality of the egg penalizes of the actors of the sector in several points: economical and sanitary. |

It is admitted that a cracked egg can't be kept sanitary. A crack represents an open door for micro-organisms: this negatively affects the quality of the hatchings at the hatchery and represents a health risk for the consumer. This is why Aaggrrii has developed an electronic egg capable of detecting shocks. Deposited in the nest of lay, it can traverse the entire production line. Connected to the wireless tablet, the results are given in real time. Thus, the tablet alerts when the recorded shocks exceed the tolerance thresholds for each part of the production chain. |

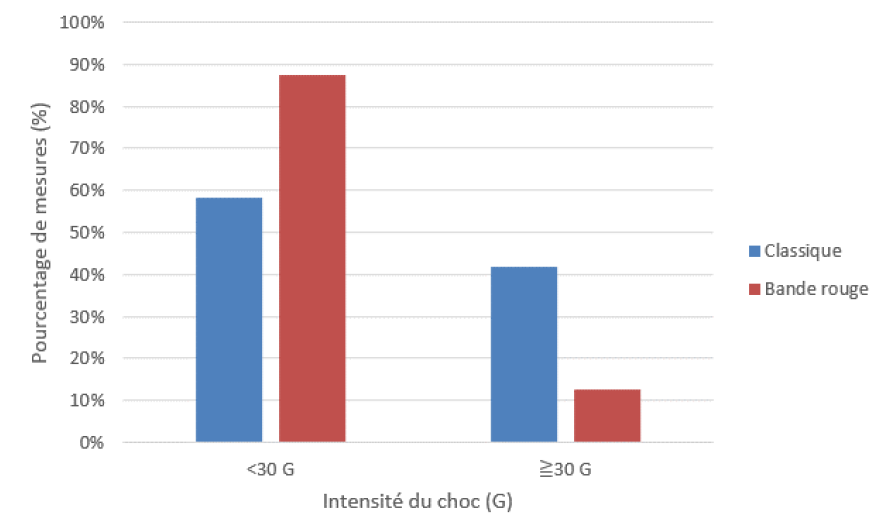

The threshold of shock intensity varies according to the production (laying or reproducing). For repeated shocks in laying hens, the threshold is set at 30G.

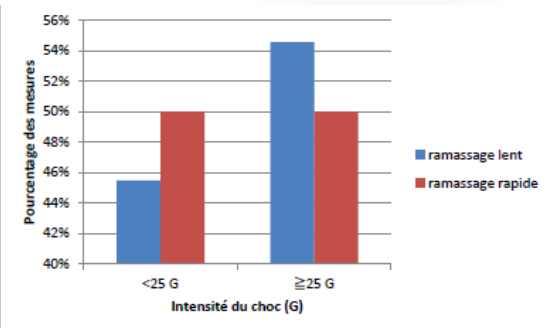

Comparison of the intensity of shocks according to the speed of eggs collection: Two collection speeds: slow and fast pickup. A quick pickup is more advisable in this breeding house than a slow pickup. |

Results of measurements taken in the entry area of a packer: Two methods are used: equipment conventionally used and damping thanks to a band. Decrease of approximately 30% of shocks stronger than 30G (threshold value) with the installation of a damping band. |